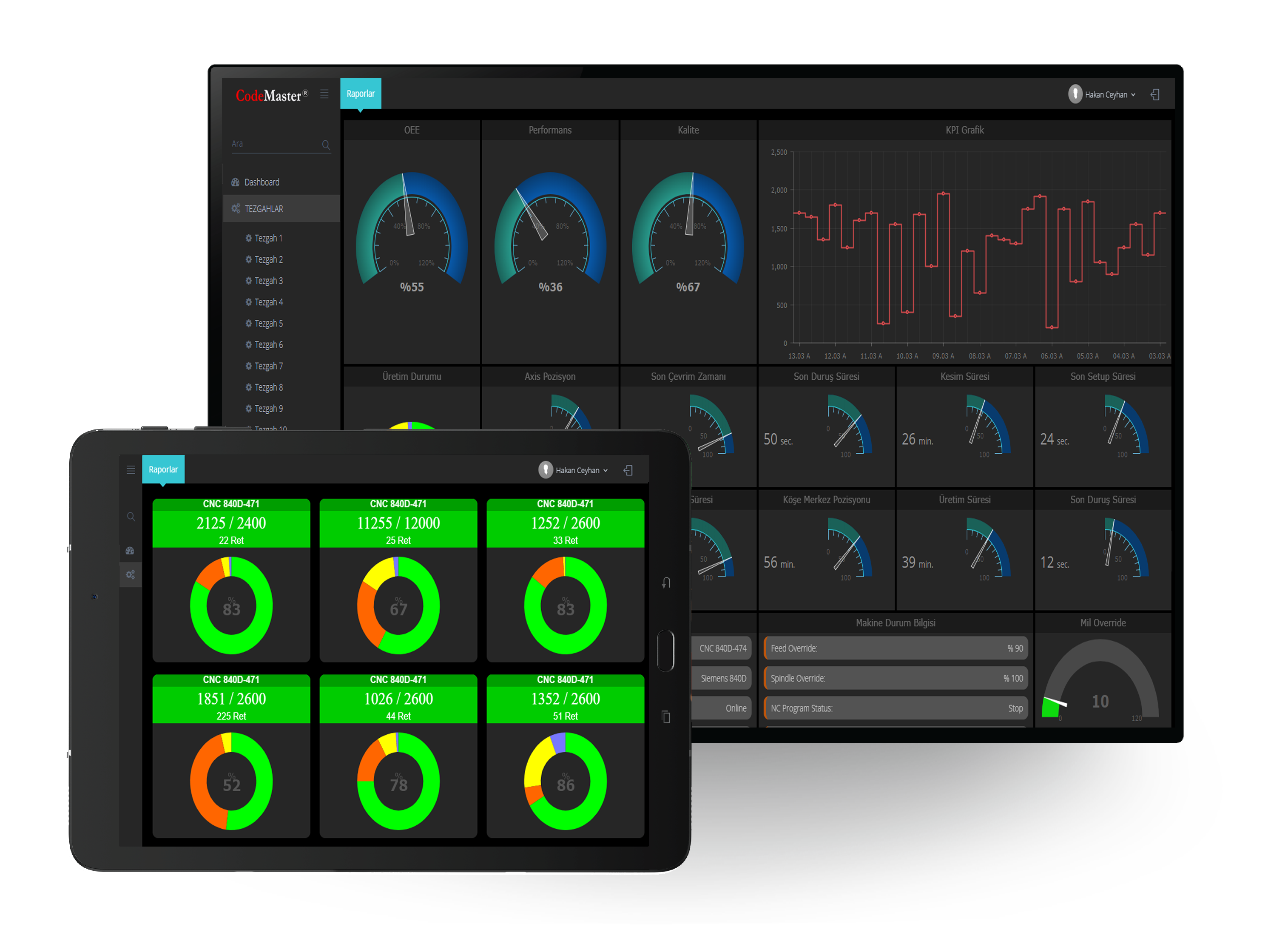

SmartCNC 4.0 is an intelligent preventive and predictive maintenance application that enables the collection and traceability of existing data on the machine tools. It enables operators and maintenance teams to receive real-time information and notifications about the machines while monitoring machine status traceability in detail through instant dashboards and mobile platforms. Smartly manage maintenance processes within the scope of preventive and predictive maintenance activities.

Safe and continuous connection to any machine or control system.

Safe and continuous connection to any machine or control system.