Visualize mold status and productivity in real-time on dashboards with next-generation web and visual objects. It is monitored as kiosk and andon as standard in the mold process.

When the pattern parameters are triggered, an SMS or e-mail message is sent to the appropriate person for immediate action by the operator or caregiver. Includes notification screen for preventive maintenance monitoring. Can be integrated with smart wristband and technologies.

SmartKalıp can run closed loop on a local web server or run smoothly on all cloud platforms.

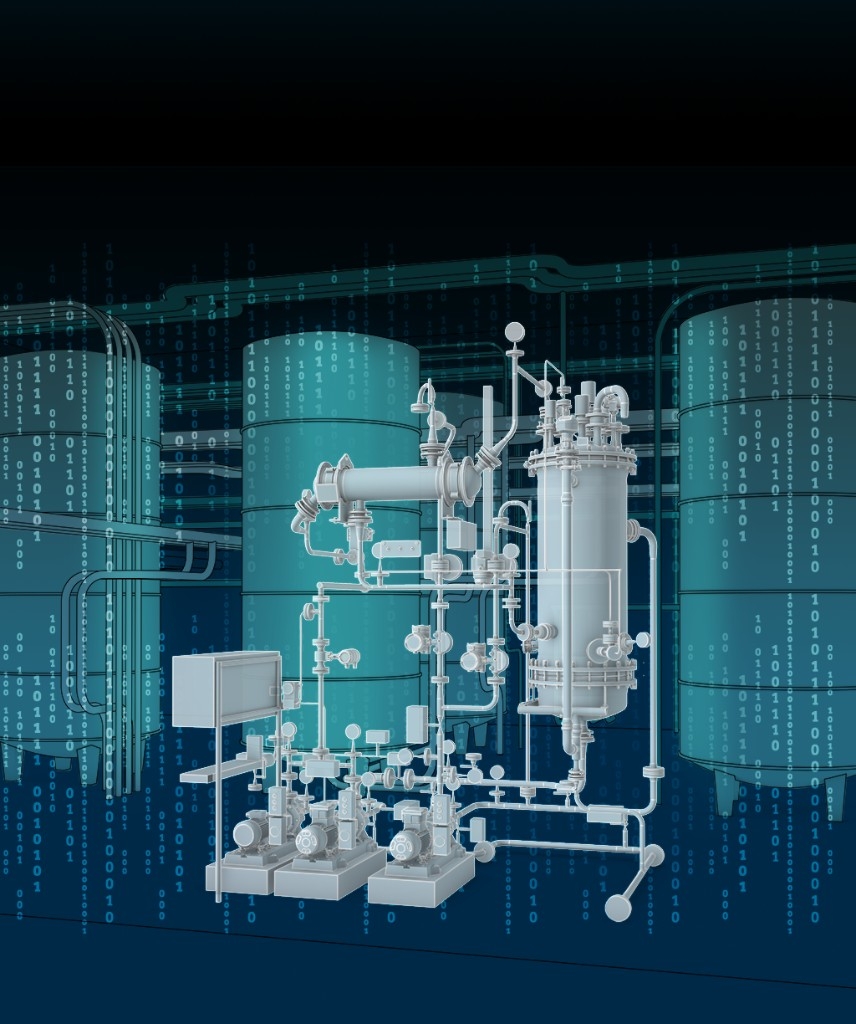

Safe and continuous connection to any machine or control system.

Safe and continuous connection to any machine or control system.