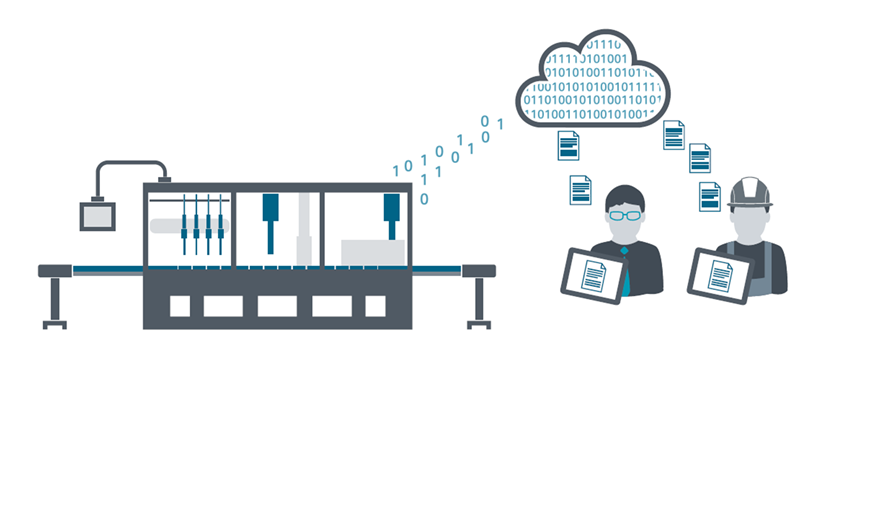

Collect all your production and maintenance data in real-time with integration into your machines and assets.

Monitor real-time machine data, alarms as a time series to help diagnose and resolve production stops and downtimes.

View and report machine usage by hour, shift, day, week, and month to understand production processes and uncover opportunities.

Alert the right person at the right time when action is needed. Report unwanted KPI changes to authorities instantly by e-mail and SMS.

Monitor, manage your machine alarms and stop instantly. Filter your desired alarm and stop parameters with active alarm-stop analysis and report machine-based or operator-based.

Make your production processes traceable on web-based and mobile platforms. Use on any device with responsive design.